Cogeneration / Tri-generation

What is Tri-generation?

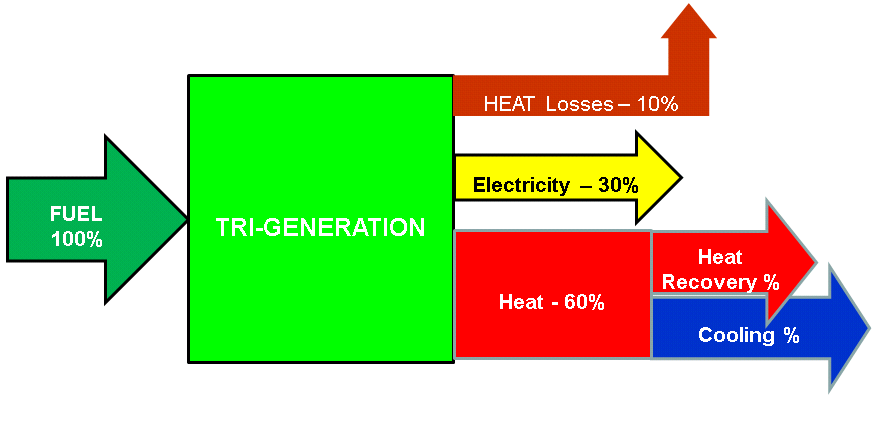

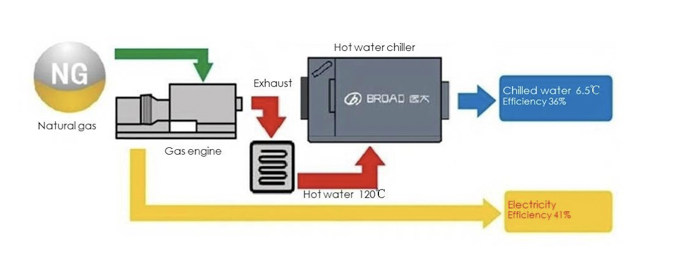

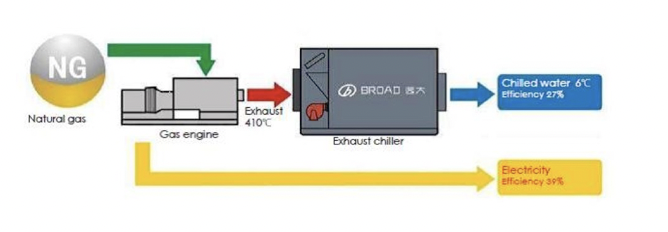

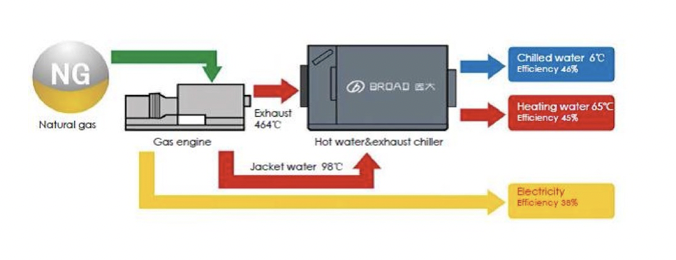

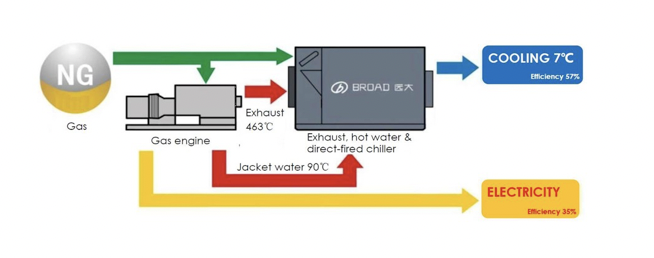

Tri-generation is the production of electricity, heat and cooling in the one process. Typically, this means a gas fired generator producing electricity and heat with the exhaust heat going to an absorption chiller which produces chilled water and hot water for air conditioning or alternatively the heat is used to heat a swimming pool. The ratio of electricity produced and exhaust heat for the absorption chiller and then the ratio of cooling to heating can be varied to meet the specific site requirements.

History

The first public electricity supply in the world was the cogeneration system implemented by Edison in 1882 to supply electricity and steam to Manhattan, New York, later converted to a tri-generation system which is now the eighth largest decentralized energy network in the world.

FR

FR EN

EN